Chips and brains

Memristors can remember past activities, just like nerve cells. Researchers are using them to build quicker chips for more efficient data analysis.

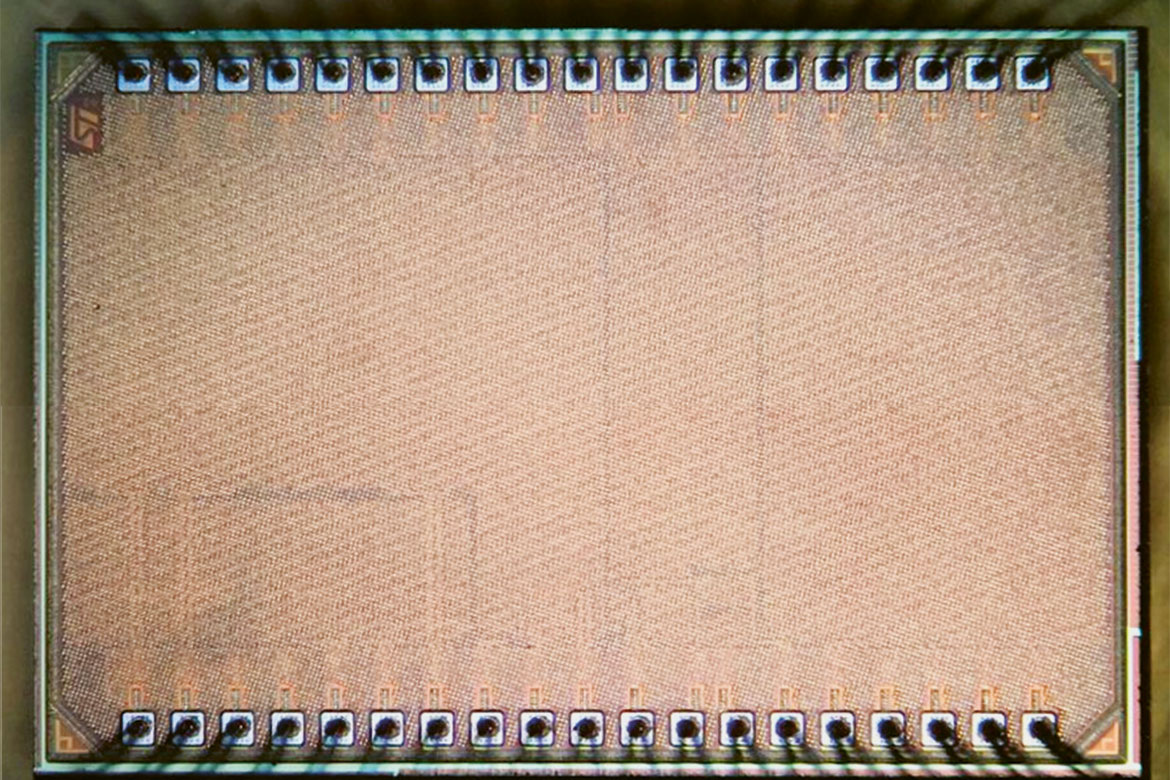

The BioNet chip imitates a network of nerve cells. It’s going to be linked to a real nerve-cell culture in order to study its activity. | Image: Stefan Schiefer

We’ve all got used to our computers getting ever quicker. But this development is now coming up against physical limitations. This is because of the current way in which computers are constructed, explains Yusuf Leblebici of EPFL in Lausanne. Processors and memory are separate units in the classical von Neumann computer architecture, and the connection between them is increasingly becoming a bottleneck: “If the processors work at high speed, it becomes more difficult to transfer the data quickly enough between memory and processor”.

The solution could lie in new structures for computer chips. New electronic components could play a role here. Researchers like Leblebici are taking biological nerve cells as their models. They want to develop neuromorphic chips whose electronic construction is like a network of nerve cells. The advantage of this is that computational and storage activities are much more closely interlinked.

Essentially, neuromorphic chips can be built with conventional electronic components – the Truenorth chip of IBM is based on this principle, for example. It digitally imitates the characteristics of nerve cells.

Leblebici is pursuing a different possibility, employing new components called memristors. Put simply, these are electrical resistors that remember the electric currents that have previously flowed through them. This is similar to the learning ability of nerve cells in the brain.

In the coming years, Leblebici will be developing several prototypes of neuromorphic chips in a collaborative project with IBM and the Institute of Neuroinformatics at the University of Zurich. He and his colleagues are proceeding on three levels. In one part of the project, they are constructing new memristors; in a second they are making circuits based on these components, such as coupling them with sensors; and a third group is busy integrating them into a total system. In this manner, Lebleb ici hopes that they will be able to carry out video recognition with one of the prototypes in just a few years.

Pardonable errors

The main advantage of chips built from memristors is their high surface density, explains Leblebici. Individual computational functions can be carried out on a hundredth of the surface of conventional chips. The price of this is a reduction in computational accuracy. Memristor chips cannot deliver results precisely to a large number of decimal places. But many other tasks require an extremely high velocity to process huge amounts of data, and one or another small error is of little consequence in such cases. Typical examples are the recognition and analysis of audio data, photos and videos. The eye won’t complain if an individual pixel has the wrong colour.

All microelectronics companies are very interested in ideas for neuromorphic chips, says Markus Kubicek from the Technical University of Vienna. Three years ago, he made the headlines with an article on the mechanisms that could one day replace flash memory. He wrote it at ETH Zurich together with Jennifer Rupp.

There is a fundamental difference between memristors and classical silicon transistors, explains Kubicek. Unlike transistors, memristors often don’t recognise the states of 0 and 1, but also something between them. This is a characteristic that doesn’t just enable them to learn, but can also be used to realise ‘fuzzy logic’ – a variant of logic that allows for unclear statements.

According to Kubicek, it’s still anybody’s guess whether chips using memristors will prevail, or neuromorphic constructions using more conventional components. There are in fact many different types of memristors. Kubicek usually uses oxides for them, such as titanium or strontium oxide. Their operating principle is founded in oxygen defects. Other groups use metal filaments, for example.

Memristors could also be made with an even higher density than up to now. To achieve this, researchers would have to realise a three-dimensional architecture – and thereby pile up the memristors one on another, so to speak. Such constructions could accommodate ‘deep learning’, says Leblebici, which is important in the development of artificial intelligence.

Surviving a billion cycles

It is often suggested that chips using memristors could use much less electricity than conventional chips. But Leblebici wants to curb such optimism a little. “You mustn’t forget that memristors need electronic circuitry on their periphery, too”, he says. And this circuitry needs extra electricity.

The biggest challenge in developing memristors is very different, says Kubicek. It’s their lack of durability. From a technical standpoint, they need to remain stable over more than a billion cycles. Sometimes even more than a thousand billion. “Most memristors today can’t yet manage that”, he says. But that could change.

The production process of memristors is still too diverse for industrial applications, says Christian Mayr of the Technical University of Dresden. He is also researching into neuromorphic structures. “Several production steps are necessary to manufacture memristors”, he explains. “That’s a problem. Manufacturers of semiconductors dislike every extra step in production because it leads to increased costs”.

Mayr believes that there are promising applications for memristors in the field of neuroprosthetics and other, similar interfaces between computers and biology. Mayr was experimenting with such systems during a research visit to Zurich from 2013 to 2015. Other interesting applications are opening up in information compression. The human eye is capable of reducing information density by a factor of 100 before the visual signal is sent to the brain, says Mayr. Perhaps neuromorphic chips will be able to do something similar in future. Whether this will involve memristors or not still remains an open question.

Sven Titz is a freelance science journalist in Berlin.