Monitoring transport routes with a digital mango

Immense efforts are invested into transporting fruit. In order to optimise ventilation and cooling, researchers have now programmed a digital twin for the mango.

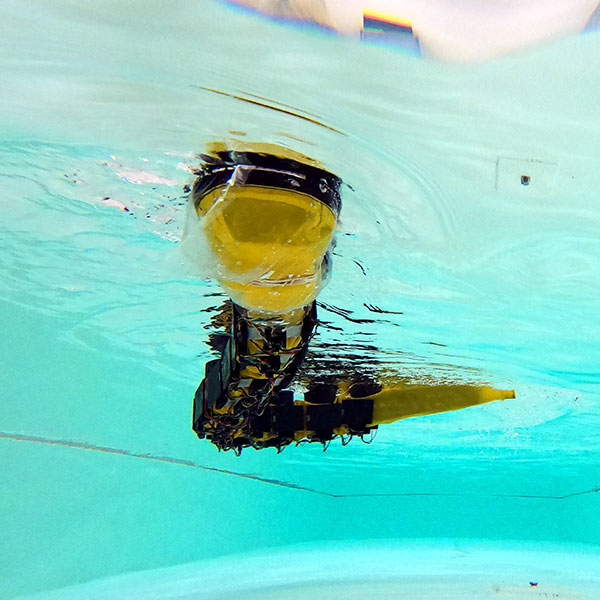

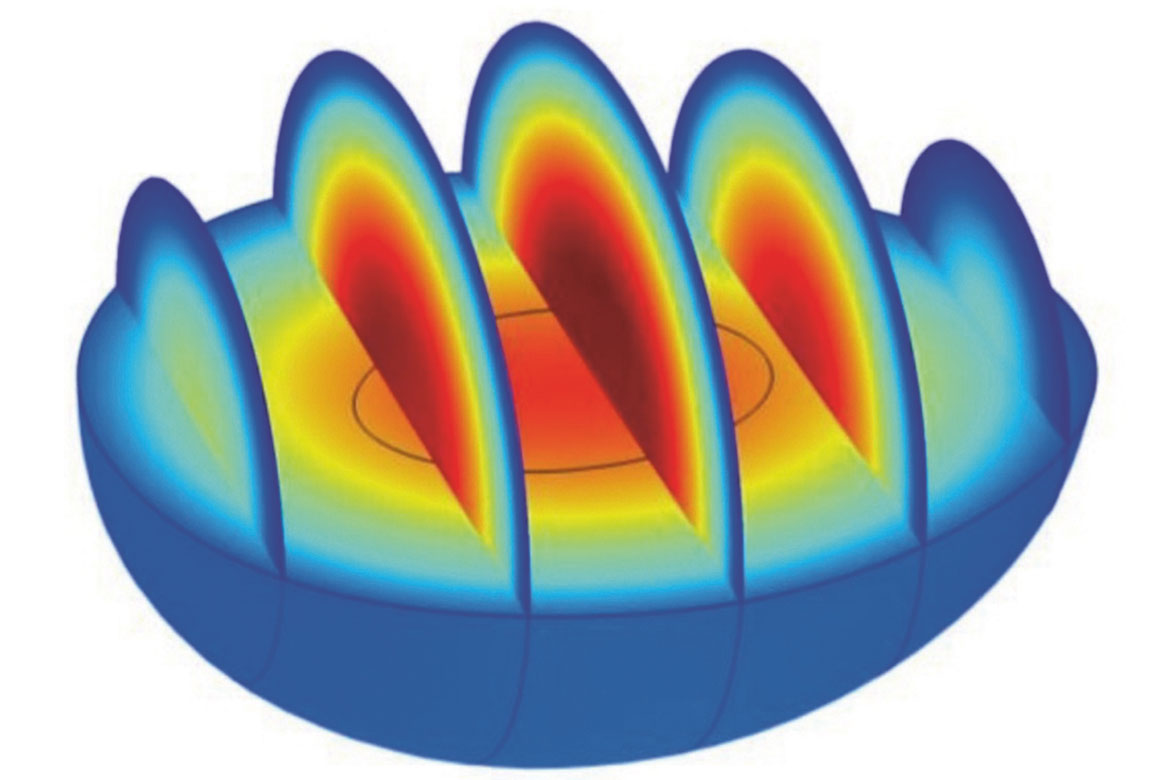

Mango on the move: its digital twin shows how the temperature changes inside the fruit. | Image: Thijs Defraeye

Whether coming from far away or nearby, fruit is transported in a refrigerated state in order to keep it fresh for as long as possible. This consumes a lot of energy, and is responsible for major emissions of greenhouse gases. And yet, according to the Food and Agriculture Organization, 13 percent of the fruit and vegetables produced in Europe go bad after harvest. For products from other regions of the world, that figure is more like 40 percent. Engineers at Empa have now published a method that could optimise transport: a digital twin of the mango. This perishable fruit is an ideal model because it lets us see exactly what happens to it when it’s transported.

Import companies already monitor their cargo, of course, measuring the temperature and ventilation in their containers. But a lot of things still remain unclear. Would less ventilation also suffice? What happens if there is an unexpected delay? “Questions like these can now be answered using the digital twin”, says Thijs Defraeye, the lead author of the study.

Defraeye and his colleagues modelled a mango in their computers, mapping out its structure and its interior metabolic processes. In this manner, they can determine the impact made by temperature changes on the quality of the fruit – such as on the resistance of its skin, its vitamin content and the quantities of acids and sugars it contains.

“With this digital mango, importers can now analyse individual fruit deliveries directly”, says Defraeye. It lets them find out how the fruit can be transported and stored in a more energy-efficient manner. And in turn, this means much more of the fruit can land on our plates in future.