MATERIALS RESEARCH

The sudden corrosion of reinforced concrete

Producing concrete that is less porous to water can prevent the corrosion of its steel core, and result in fewer emissions.

The concrete towers of the Arthur Ravenel Jr. Bridge in Charleston (South Carolina) have to be able to withstand water corrosion for a long time. | Image: David Martin/Unsplash

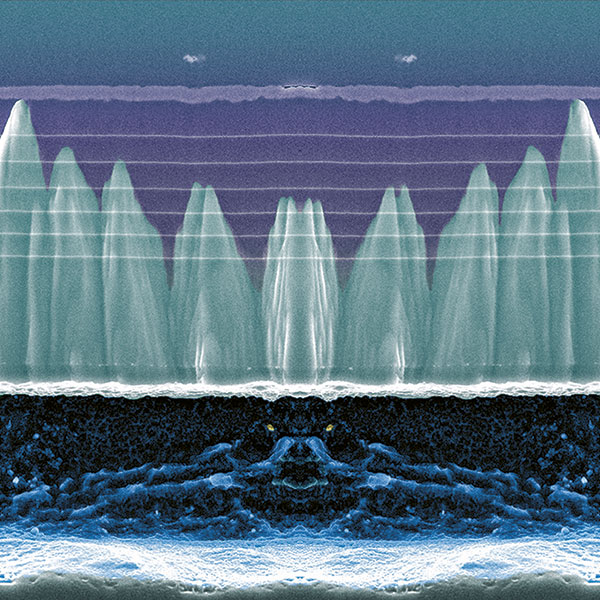

It has been known for decades that steel corrosion in porous media such as concrete will only proceed rapidly if a specific level of internal moisture is reached. However, the moisture condition in such materials can fluctuate constantly. Up to now, little attention has been paid to how this dynamic influences the corrosion rate. But a team led by Ueli Angst from ETH Zurich, in collaboration with the Paul Scherrer Institute, has for the first-ever time been able to visualise the significant effect that water absorption has on the corrosion rate of steel reinforcements.

To do this, the researchers used neutron imaging in order to visualise the path taken by water through the pores in a piece of cement mortar. At the same time, they used electrochemical measurements to track the corrosion rate of the steel embedded in it. They found that the corrosion was negligible in dry mortar, but that it increased to a rate of around thirty micrometres per year at the exact moment when the water touched the steel. This is a rate that is relevant in practical terms. “The corrosion is literally triggered by the water that penetrates the concrete”, says Angst.

These findings could be crucial to achieving a more environmentally friendly means of producing concrete. Until now, it has contained a large proportion of so-called ‘clinker’, which is burned at high temperatures and whose production is correspondingly energy-intensive and results in high emissions. Carbon dioxide is split off chemically to leave a more alkaline material, as a high pH value is considered to be the main factor for protection against corrosion. “Our results have shown that the steel does not necessarily corrode, even if the pH is lower”, says Angst. “It only becomes precarious if the steel also gets wet”. Future research into the microstructure and water absorption of concrete could therefore pave the way for a low-emission concrete that has a lower proportion of clinker.