REPORT

From Bern to the Moon, Mars and Venus

In a cleanroom at the University of Bern, high-precision instruments are tested for use on the Moon, Mars and Venus. Swiss researchers are here providing cutting-edge technology for international space missions.

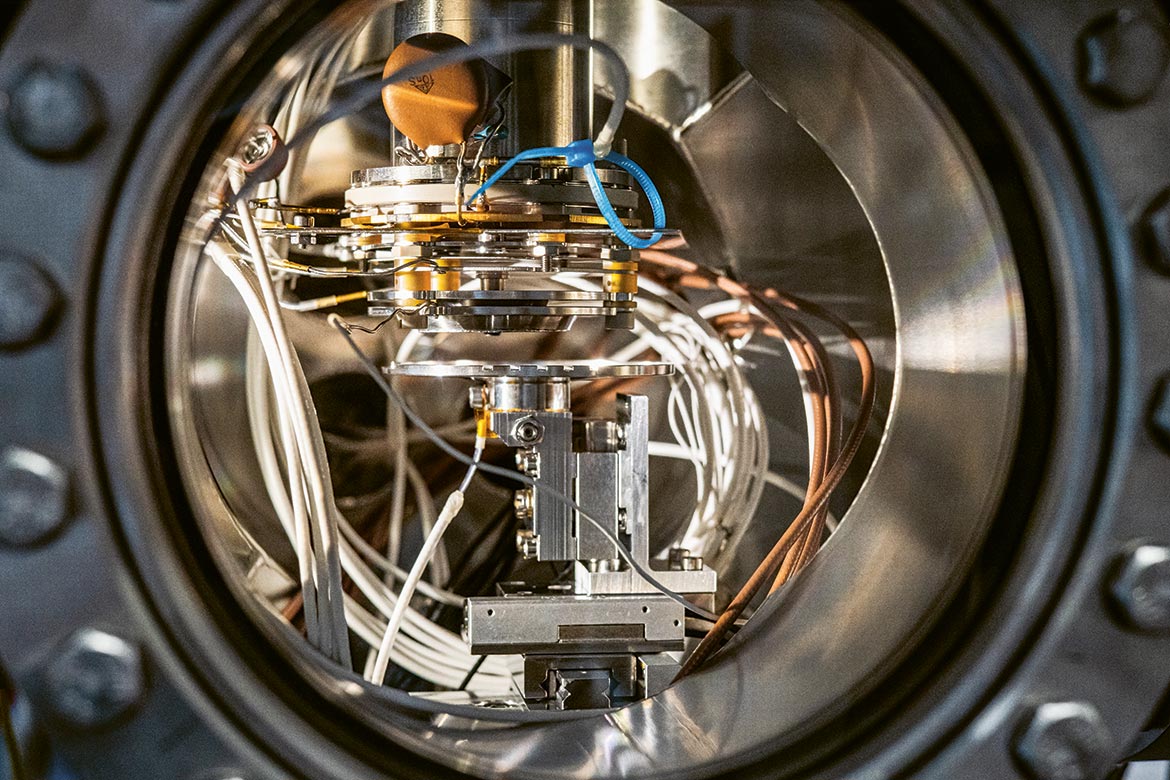

These highly sensitive, incredibly precise instruments for conducting research in space have to cope with massive radiation and gravitational forces. | Image: Ruben Hollinger

If you want to analyse the composition of rock, sand, dust or gases anywhere far away from Earth, what you need is a mass spectrometer. It’s the jack-of-all-trades if you need precise chemical analyses on a space mission. The University of Bern plays in the world’s ‘champions league’ when it comes to developing these devices. “There are only four research groups that can produce this kind of quality. We are one of them”, says Andreas Riedo, the team leader of the group Space Research & Planetary Sciences of the University of Bern. They are currently testing new devices for missions to the Moon, Mars and Venus. Their goals include finding evidence of extra-terrestrial life in the Solar System.

Even before you enter their development laboratory, it becomes clear why it’s so difficult to build a high-precision measuring device for use in space. Riedo holds a protective suit under our noses. It’s a kind of mackintosh with a zipper and a hood that buttons up to your chin. What about our photographer’s camera? That’s allowed, but Riedo gives it a thorough blast with high-purity nitrogen. This lab is a so-called cleanroom. Textile fibres that could float around freely are definitely not wanted here. The same applies to human hair and even dandruff. “They could contaminate our samples and thus falsify the results of our measurements”, says Riedo.

There’s not a lot of space in the clean room. There are two testing tables that stand on air-filled cylinders that compensate for any vibrations. “The main railway station is right next door, and that’s a problem”, says Riedo. “When a train leaves the station, the floor shakes here”. Mass spectrometers are positively allergic to that.

A flat box lies across the entire width of one of the tables. It’s a very powerful laser, and a core component of the device. Salome Gruchola, a doctoral student in physics, explains how it works: “It generates light with a kind of flash unit similar to what you have in the camera of a smartphone. This is then compressed over several steps until it forms extremely short pulses of light in the range of a quadrillionth of a second”, she says. Her doctoral research includes testing the spectrometer and preparing it for its journey into space.

The laser beam is ultimately so highly focused that it is over ten trillion times more powerful than the sunlight that reaches the Earth. “One shot to the eye would suffice to blind you completely”, says Gruchola. They have the latest laser safety goggles that wouldn’t be out of place on a Martian fashion parade, but they still wouldn’t be enough to prevent eye damage. To reduce the risk of accidents, rings and other jewellery are banned from the lab. If metal surfaces get caught in the laser beam by accident, they’ll act like miniature disco balls and scatter the beam uncontrollably across the whole room. Metal tools such as Allen keys are blackened so that they no longer reflect light.

A series of mirrors directs the beam into a vacuum chamber the size of a cool box. This is where the mass spectrometer is located. The vacuum is needed because any air left in the chamber could lead to “high-voltage breakdowns”, says Riedo. In other words, an arc of light would form between the individual components, some of which are under high voltage. This would either result in invalid measurements, or simply break the device altogether.

The vacuum chamber won’t be necessary on the Moon. But researchers on Mars will need a small chamber since the very thin Martian atmosphere would still suffice to cause malfunctions.

The laser beam is ultimately directed at a rock sample; in the case of an experiment on the Moon, it will be a dust sample. When it hits its target, it releases a tiny cloud of charged particles: ions. “The rock is basically vaporised”, says Gruchola. Now all they have to do is to sort the particles. This task is performed by several metal rings arranged closely together, one behind the other. They are electrically charged, and direct the ions toward the detector.

“The time it takes for them to arrive at the detector depends on their weight and their charge”, says Gruchola. “Lighter ions get there first – such as hydrogen ions. Then come the heavier ones, such as oxygen or silicon ions”. The computer plots their arrival as a sort of ‘fever curve’. Each deflection of the curve represents a group of particles. The extent of this deflection indicates their number. “Armed with this information, we can determine the exact elemental composition of the rock”, says Gruchola.

This device is due to be installed in a lander that will fly to the Moon in just a few years’ time in NASA’s new Artemis programme, the successor to its Apollo programme of the 1960s. It is hoped that analysing the lunar dust will help to solve certain questions about how the Moon, the Earth and even the rest of the Solar System were formed.

“NASA has even already asked us about an unmanned Mars mission in the 2030s”, says Riedo, not without a sense of pride. “This will involve drilling into the surface of the planet and looking for traces of lipids on site in the drill cores”. Since the membranes of cells and bacteria are made of lipids, detecting their presence would be a strong indication of life on Mars. “We have recently been able to prove that our mass spectrometers are very well suited for detecting such substances”, he says.

Fit for space

One problem with carrying out analyses far from Earth is the limited data connection. This is why Gruchola’s doctoral research also entails investigating how to automate data analysis. “I am trying to teach an AI what data are interesting, and what aren’t”, she says. “Once I’ve trained it, it will be able to decide on the lander what should be sent back to Earth”.

These devices don’t just have to be self-sufficient. They also mustn’t break under any circumstances. For example, they mustn’t be scuppered by a broken screw or a sensor that shifts out of place. “This instrument might be flying through space for ten years”, says Riedo. “So it has to be very, very robust”.

Coping with the initial rocket launch is another hard nut to crack. “The instruments are designed to withstand forces of 100G – in other words, a hundred times the Earth’s gravity”, says Riedo. In order to simulate such forces, each component is tested on the so-called shaker – a giant vibrating machine that can recreate the launch effect of any type of rocket. Every single component has to survive this ordeal intact.

“Radiation is another challenge”, says Riedo. A mass spectrometer from the University of Bern is on the JUICE mission to Jupiter that was launched in April of this year. Jupiter is a giant planet with a strong magnetic field that produces a belt of intense space radiation. When the spacecraft nears this belt, it will start taking measurements. “The radiation there is as high as in a nuclear reactor”, he says. “These are extreme conditions for our instruments”. If they are to survive, they have to be well shielded.

On Earth, people usually say that bigger is better. But different rules apply on a space mission. “Depending on the mission, flying a single kilo in weight to its destination can cost up to a million francs”, says Riedo.

This is why, after it’s been through its development phase in the lab, every mass spectrometer is then optimised for the journey, which often means building it in a scaled-down form. This is the task that’s currently occupying Peter Keresztes Schmidt, a doctoral student. His goal is truly ambitious: the entire device has to weigh between ten and 15 kilos, and its volume can’t be greater than the contents of a paper carrier bag.

A small heap of artificial moondust

In this configuration, the laser itself is only as big as a pack of playing cards. Keresztes Schmidt has already installed the mini-sized mass spectrometer in its vacuum chamber. “Now I have to check the settings, the measurements, and also whether or not it’s been constructed robustly enough”. To this end, he has just put some ‘moondust simulant’ on the slab for samples in the vacuum chamber. He explains what it is: “This is artificial moondust that’s been created on Earth and more or less has the same properties as the real thing. Either way, it’s good enough for our tests”.

During this testing phase, he’s working intensively with the engineering department just a few floors above him. But he’s also liaising with NASA, which is having the actual lander built in the USA. “At present, we’re discussing whether we should use a conveyor belt to bring the moondust to the mass spectrometer, or whether the spectrometer should be mounted on a robotic arm and then guided to the dust”, says Keresztes Schmidt. He still has until 2026 to get everything right – and then the spectrometer ‘Made in Bern’ will blast off for the Moon.