MICROOPTICS

Ultra-high speed fibre optics using frequency combs

A Swiss start-up wants to multiply the speed of data in fibre optics and reduce electrical consumption. We look at a microchip that may help do both.

In astronomy, a frequency comb (dots) measures the spectrum (lines) of a star. The colours shown here are actually too far apart and are for illustration purposes only. | Image: ESO

Fibre optics play an unavoidable role in Internet infrastructure. They transport data farther and faster than copper cables. They’re made of a plastic or glass thread and conduct a laser beam that – in very broad strokes – communicates digital information by pulsating either ‘0’ or ‘1’. It’s a little like morse code with a torch, but in binary, and above all much faster!

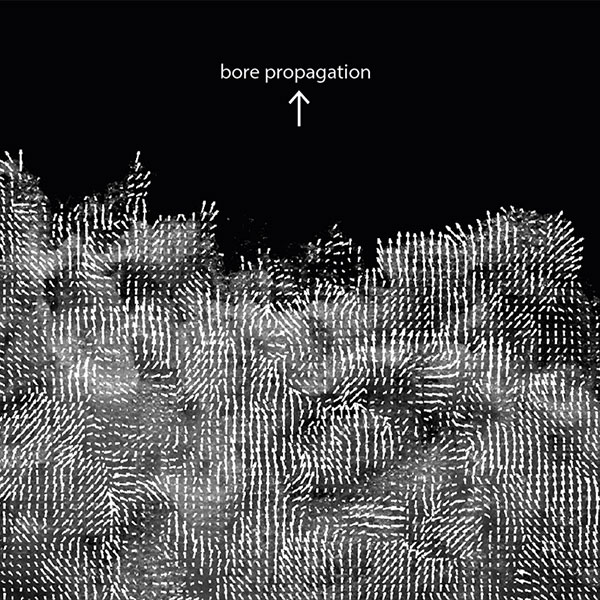

To multiply the speed of data, we’ve been trying since the 1990s to divide the laser beam into several channels or ‘frequency combs’. The principle consists in creating small portions of the light spectrum, equally sized between ultraviolets and infrareds across the range of visible light. Rather than a smooth curve, the spectrum becomes a row of regularly spaced teeth, hence ‘comb’.

Once the laser beam is converted, each tooth can transmit an independent signal. In theory, it means we can send several data streams – even hundreds – on a single fibre-optic cable. In practice the principle has been demonstrated in the lab and is now entering into commercial applications.

One hundred fibres in one

This is the mission that the businessman and former EPFL and CSEM researcher Maxim Karpov has given himself. He created the start-up Enlightra in 2021. His technology uses frequency combs to improve the relationship between the speed (i.e., bits per unit of time, Ed.) and the energy of optical transmissions. Almost immediately, the company joined the prestigious club of firms supported by the start-up accelerator Y Combinator, which gave rise to Airbnb, Dropbox and Reddit. It currently has 14 employees and has already delivered its first products to Germany and the USA.

Enlightra manufactures microcomb technology in the form of small integrated components in a chip. Laser beams are injected into the circuit in the form of a loop. This micro-resonator converts the laser beam into multiple colours. “The crucial point is that contrary to what happens in a prism, the light does not separate in every direction”, says Karpov.

“The colours are different, but they remain on top of each other in the same beam”. In other words, the light signal continues to act like a laser, which is essential for it to be sent along an optical fibre.

Each colour – or each comb tooth of the split-up spectrum – can be used as a separate channel. The prototypes built by Karpov count around one hundred. It’s like combining 100 fibres into one. The electrical consumption on the other hand is divided by ten for the same speed, in comparison with traditional optical systems.

Technology for data centres

The market for Karpov’s start-up is above all data centres, where it can introduce one percent savings in electricity usage. It’s far from anecdotal: today data centres make up around three percent of the world’s energy consumption – a figure that grows every year.

According to Brendan Heffernan, a microcomb expert and researcher in the company IMRA America, which is unrelated to Karpov’s work, the approach is persuasive. “In the short term, I think that microcombs could first become a key technology in the niche areas of data transmission. As with all emerging technology, there are some engineering problems to solve, but there’s a lot of talented minds around the world working to that end”.

In the long term, microcombs could continue to take over until homes are connected to the internet using fibre optics, thinks Karpov. “But for now, that’s not where the need is”.