HEATING TECHNOLOGY

Heat pumps pass the stress test

Reciprocating compressors can cope with high temperatures. This means that the industrial use of heat pumps isn’t far off.

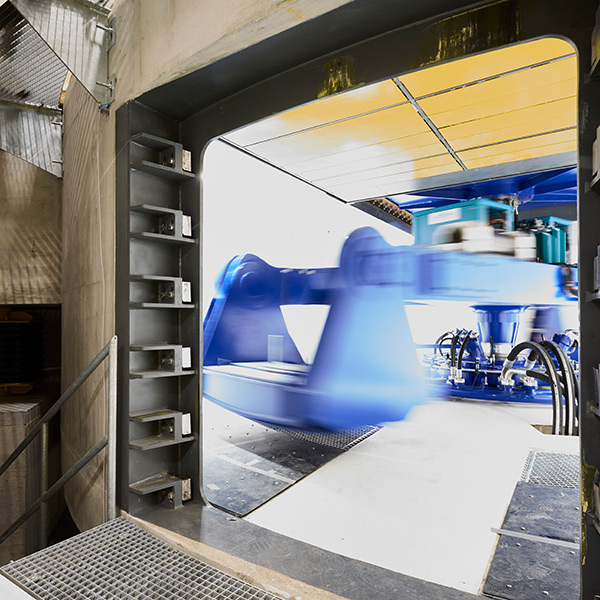

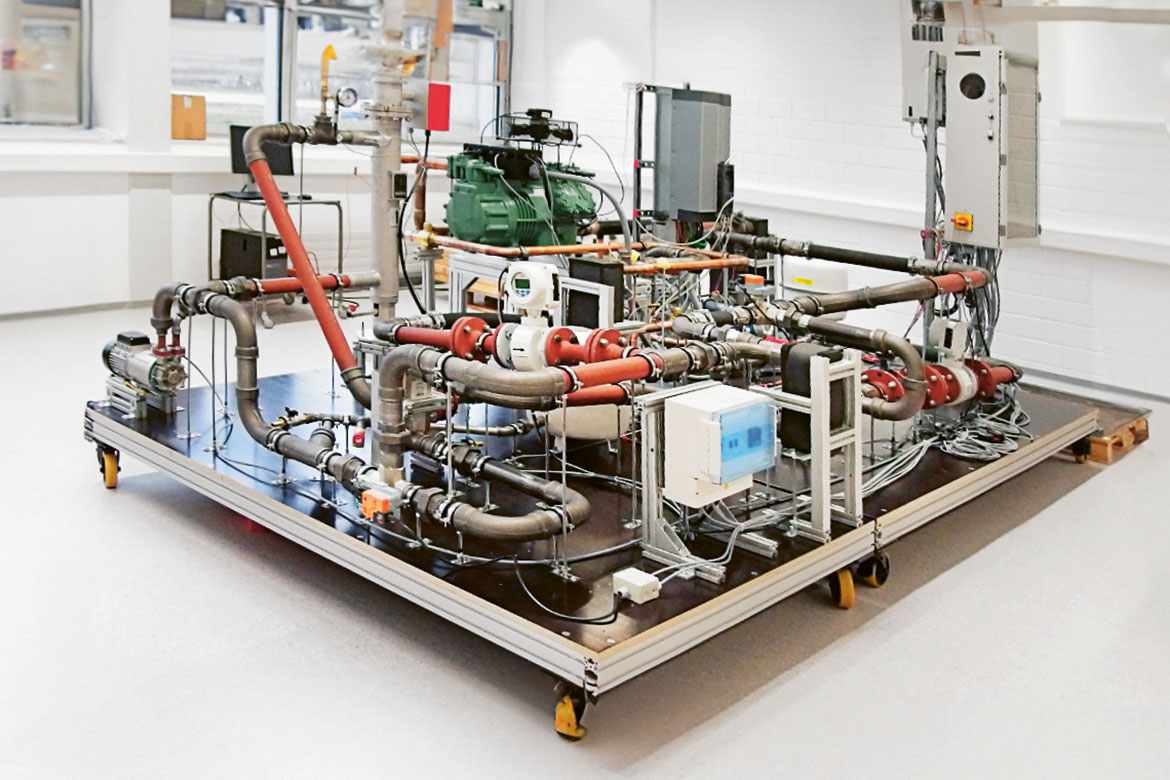

This standard heat pump was set up in a lab and tested, proving that it can function at industrial temperatures. | Photo: Ostschweizer Fachhochschule

Producing paper or plastic means achieving temperatures of up to 200 degrees Celsius. This usually involves burning fossil fuels such as natural gas. However, it could be done in a more climate-friendly way using heat pumps. This has been shown by a study conducted by Stefan Bertsch and Leon Brendel from the University of Applied Sciences of Eastern Switzerland. If the machines in question were powered by electricity from renewable sources, then emissions would be reduced to almost zero.

Heat pumps are not yet able to withstand this, but Bertsch and Brendel have demonstrated that standard components can already cope astonishingly well with high temperatures. They subjected a reciprocating compressor to heat stress, exposing this important component for over a thousand operating hours to temperatures for which it was never designed. It ran at more than 120 degrees Celsius for 300 hours and at 150 degrees for 30 hours; its peak temperature even went up to 188 degrees.

“A compressor won’t disintegrate because of that”, says Bertsch. “But we did expect that there would be a loss in efficiency, that the motor winding would melt, or that other serious damage would occur”. But none of that happened.

When the researchers dismantled the compressor into its constituent parts, they found that the device had hardly been affected at all; only the cylinder head sealing had suffered, as expected. “We are optimistic that heat pump manufacturers will soon approve significantly higher temperatures for off-the-shelf products”, says Brendel. Further tests are still needed, and some parts would need to be replaced. But it’s possible.