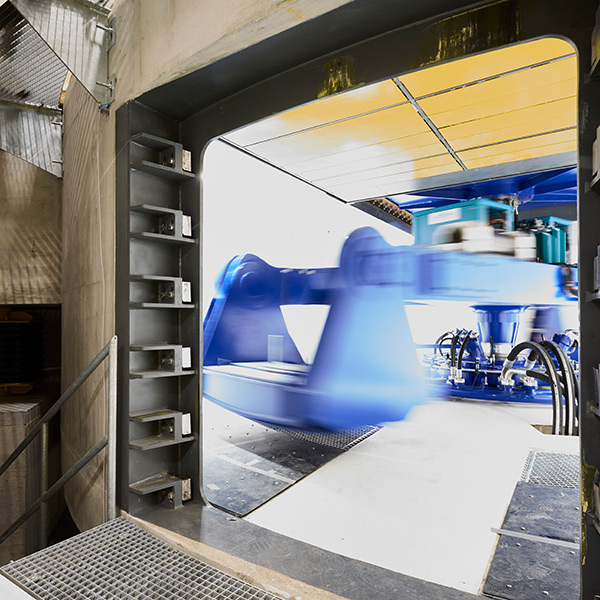

The springs of silence

This eerie arrangement of tiny, spring-like structures has one goal: noise reduction. It’s 50 cm square in size, and might one day be used in buildings, cars and planes, says its creator, Andrea Bergamini from Empa in Dübendorf. It’s a remarkable example of phononic crystals: structures arranged with a precise periodicity so as to absorb or deflect sound waves. “It’s a pretty recent field of research”, says Bergamini. “Its name refers to phonons, which are vibrations propagating in solids, and was inspired by its older brothers, the photonic crystals that are able to block or redirect light”. The structure is manufactured with a 3D-printing technique called selective laser sintering (SLS), where polymer powder is deposited layer by layer and melted by a laser to consolidate it. “We’ve created spring-like shapes in order to change the way the overall structure reacts to incoming sound waves: the 4 cm-wide rings cannot only move left, right, forwards and backwards like tiny balls of matter, but can also twist around their axis of symmetry”. This additional movement enabled the researcher to explore more configurations before manufacturing it. “Our goal was to create a material that is reasonably small, and stiff so that it can bear loads, but also light enough for automotive or aerospace applications. It’s a difficult combination, but we’ve succeeded. Our device attenuates 99 percent of 800 Hz waves, which is the typical frequency range of vowels in human speech”. The Empa team will insert their structure into a sandwich of polymers to test it as room panels. As the arrangement is largely empty, it lets most light through. While too thick (10 cm) to serve as a window, it could be used in sound-proofing panes separating rooms without blocking out daylight. CC BY-NC-ND

Bild: EMPA/Fotograf Beat Geyer

This eerie arrangement of tiny, spring-like structures has one goal: noise reduction. It’s 50 cm square in size, and might one day be used in buildings, cars and planes, says its creator, Andrea Bergamini from Empa in Dübendorf.

It’s a remarkable example of phononic crystals: structures arranged with a precise periodicity so as to absorb or deflect sound waves. “It’s a pretty recent field of research”, says Bergamini. “Its name refers to phonons, which are vibrations propagating in solids, and was inspired by its older brothers, the photonic crystals that are able to block or redirect light”.

The structure is manufactured with a 3D-printing technique called selective laser sintering (SLS), where polymer powder is deposited layer by layer and melted by a laser to consolidate it. “We’ve created spring-like shapes in order to change the way the overall structure reacts to incoming sound waves: the 4 cm-wide rings cannot only move left, right, forwards and backwards like tiny balls of matter, but can also twist around their axis of symmetry”. This additional movement enabled the researcher to explore more configurations before manufacturing it. “Our goal was to create a material that is reasonably small, and stiff so that it can bear loads, but also light enough for automotive or aerospace applications. It’s a difficult combination, but we’ve succeeded. Our device attenuates 99 percent of 800 Hz waves, which is the typical frequency range of vowels in human speech”.

The Empa team will insert their structure into a sandwich of polymers to test it as room panels. As the arrangement is largely empty, it lets most light through. While too thick (10 cm) to serve as a window, it could be used in sound-proofing panes separating rooms without blocking out daylight.